Converting Waste to Energy: How to Make it Happen in Your Community

The Institute for Local Government (ILG) Sustainability Team members who contributed to this article include Karalee Browne, Melissa Kuehne and Steve Sanders. For more about ILG’s sustainability program, visit www.ca-ilg.org/sustainable-communities.

As cities work to meet the state’s waste diversion requirements and goal of diverting 75 percent of California’s waste by 2020, they are turning to innovative strategies like anaerobic digestion to convert waste into energy. Anaerobic digestion is a natural process that breaks down organic materials — such as food scraps and green waste — into gas and fertilizer. It takes place in an oxygen-free environment in an enclosed container or a natural environment sealed off from the air, like a marsh, bog or wetland, and produces a gas that can be captured and converted to energy.

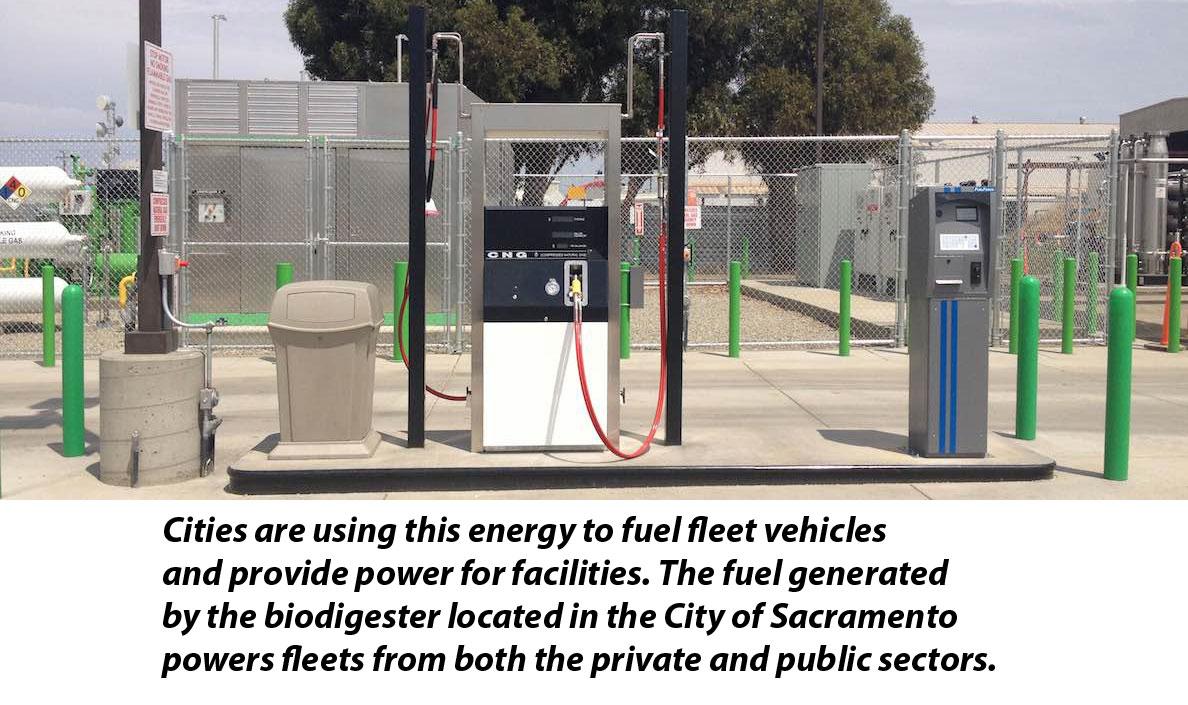

Cities are using this energy to fuel fleet vehicles and provide power for facilities. Transforming organic waste materials into energy can also save money, reduce greenhouse gas emissions and produce compost for fertilizer.

The Anaerobic Digestion Process

Organic material such as food waste or green waste goes into large enclosed “digesters” typically located adjacent to other waste-recovery facilities.

The technology used to process food waste is called wet anaerobic digestion. When a facility primarily uses other organic green waste, the process is known as dry anaerobic digestion.

Anaerobic digestion produces biogas, which is primarily methane and carbon dioxide. Biogas can be used as a transportation fuel — it is the equivalent of compressed natural gas — or for producing electricity.

A second product of the process is a substance called digestate, which is a solid and/or liquid residual product that can be used for composting and fertilizer.

Anaerobic digestion facilities can be stand-alone facilities or located at landfills, composting or recycling facilities or wastewater treatment plants. Locating such facilities close to the source of the input materials, existing processing facilities or the destination for the products can result in process efficiencies, simplified permitting, reduced impacts and cost reductions.

Benefits of Anaerobic Digestion

Local jurisdictions with anaerobic digestion projects in their communities report a number of benefits including cost savings, the ability to meet greenhouse gas reduction goals and state regulations, increased community pride and recognition of their role as an environmental leader.

When considering an anaerobic digestion facility, communities have the option to produce electrical energy or an equivalent of compressed natural gas. The electrical energy can be used for the facility and/or adjacent facilities. The compressed natural gas equivalent can be used to fuel vehicles that run on natural gas, including dump trucks, delivery trucks and school buses. Either energy choice reduces the amount of energy that the agency purchases from an outside source and can result in significant savings.

Sacramento Biorefinery Serves Large Region

The City of Sacramento is home to an anaerobic digester biorefinery that benefits an eight-county region. In 2011 the County of Sacramento sought to convert a fully permitted, yet unused, transfer station into a useful asset. The county issued a request for proposals from companies interested in waste conversion. Two private-sector firms partnered to create a biodigester and fueling station on the property, using grants and loans from CalRecycle and the California Energy Commission as well as permitting assistance from the City of Sacramento.

The facility can process 40,000 tons of food waste per year from area restaurants, food processors, hospitals, elementary schools and supermarkets.

Public agencies as well as private companies throughout the region use the 730,000 gallons of biofuel produced annually. The biofuel powers all of the natural gas trucks of the local trash and recycling collection fleet (24 of 55 trucks), as well as a portion of the city’s and county’s waste fleets, security cars, six California State University Sacramento commuter buses, school buses and two local catering companies’ vehicles.

The waste gas, which is not clean enough to use for transportation fuel, produces 1 million kilowatts (kW) of electricity that powers both the facility and the fueling station. The digestate is used to produce 8 million gallons of organic soils and fertilizers for area farms.

Public-Private Partnership Launches Pilot Project

Located just north of the City of Marina, the facilities of the Monterey Regional Waste Management District include a pilot project that has been operational since March 2013. This small anaerobic digestion facility boasts a 5,000-ton input capacity and can produce 100 kW of electrical energy daily.

The waste management district considered anaerobic digestion as a way to keep organic material out of the landfill and put it to better use. A private-sector company was looking for an opportunity to demonstrate the practicality of its new technology. The district agreed to host the pilot project and provide the site, and in exchange the company is providing the system for a 5-year term without requiring the $3 million purchase up front.

The digestate produced by the facility goes to a private firm that rents part of the district’s land for an on-site composting facility. This firm is responsible for marketing and selling the compost, primarily to local vineyards. The district also worked cooperatively with the hospitality industry to create an “Organics to Energy” brand and an informative website that showcases the project and the participating hospitality businesses sending their food waste to the facility.

“The business community was instrumental in making this project a success,” says Jeff Lindenthal, director of community programs for the Monterey Regional Waste Management District. “They are proud to know that their food waste is going to a state-of-the-art facility where the methane is being converted into electricity for local use.”

Perris Houses One of World’s Largest Facilities

One of the largest anaerobic digestion facilities in the world is under construction in the City of Perris. The 52-acre facility is funded largely by grants from the South Coast Air Quality Management District, CalRecycle and the California Energy Commission. The city’s waste hauler is developing the project, which is being rolled out in four phases, with the first coming online in October 2015.

Subsequent phases will enable the facility to produce 4 million gallons of biogas each year. When completed, the project will have the capacity to convert over 320,000 tons of organic wastes into renewable natural gas, which is the cleanest of all transportation fuels — six times cleaner than traditional natural gas.

The City of Perris supported the project by expediting the proposal to help meet state grant deadlines and providing assistance in getting approvals through the local Airport Land Use Commission. “This system will allow us to recover as much as 85 to 90 percent of the waste stream, which dramatically improves our ability to meet the state’s diversion mandate,” says Clara Miramontes, director of development services for the City of Perris.

Finding the Funds

As with most recycling facilities, a new anaerobic digestion facility needs a source of funding to build the site and install the equipment. Numerous grant programs available through state and regional agencies can be used to underwrite these one-time costs. Long-term costs are often similar to fees charged at landfills and thus can often be covered with existing methods.

Tips on Implementation

Cities that have succeeded in bringing anaerobic digestion facilities to their communities offer these suggestions based on lessons learned:

- Explore and address any major barriers (such as air quality regulations or issues raised by neighboring jurisdictions) and community concerns (such as noise, traffic and air quality) before launching such a project;

- Consider which outputs will work best for your community — electricity or biogas used for fuel;

- Determine the right size facility for your community to balance supply and demand, and make the most of operational efficiencies based on size;

- Pre-zone or permit land for composting and/or anaerobic digestion to reduce local permitting delays; and

- Consider buying trucks powered by natural gas in anticipation of biogas production.

Related Resources

For more information on anaerobic digestion strategies and funding and siting recycling infrastructure and facilities, visit www.ca-ilg.org/recycling-resource-center.

For an overview of available financing options, visit www.ca-ilg.org/document/financing-recycling.

Mandatory Commercial Organics Recycling (AB 1826) www.calrecycle.ca.gov/recycle/commercial/organics/

CalRecycle www.calrecycle.ca.gov/

For more information on the Sacramento example: www.cleancitiessacramento.org

For more information on the Marina example: www.organicstoenergy.org

For more information on the Perris example: www.eisenmann.us.com

Photo credits: Courtesy of Monterey Regional Waste Management District (top and middle); Courtesy of City of Sacramento (bottom)

This article appears in the June 2015 issue of Western City

Did you like what you read here? Subscribe

to Western City